*****************************

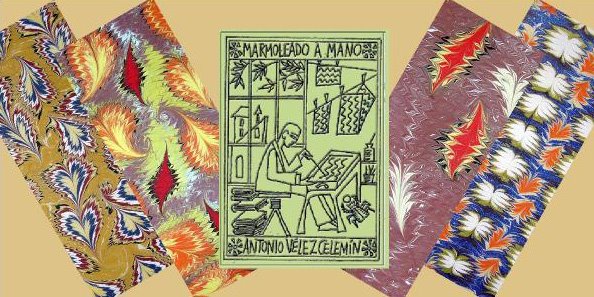

The "Cathedral" pattern,

realized with a comb of only two millimeters of separation between its needles,

impossible to construct without the method of Charles W. Woolnough.

When one needs some instrument for the practice of marbling, combs, tray or almost any other thing, it is very difficult to find it on the market, although they are some specializing shop, especially in Istanbul … then, the best solution is to make it by himself. In this article I am going to explain three different methods that I use to make my combs. I hope that this reportage helps to do them to the people who need them.

The illustration from Woolnough's manual.

But before starting, I want to pay my debts. The method more refined that I use was spread by Charles W. Woolnough, the author of a precursor manual of marbling in the XIXth century. There a revealing diagram appears, but I confess that I did not manage to understand the method until Joan Ajala intervened and gave me explanations. So I owe gratitude to Joan for her explanations and to the big master for his generosity on having revealed, in that epoch, this system. But also I owe gratitude, and very much, to Manuel Valero Mor, because his work illustrates these lines. He had the gentleness of accompanying me one morning taking many of the following photos and he completed his determination making several and precise diagrams. A great thank you, Manuel.

***

There are two types of combs. Some of them mount thick needles and serve to section the painting, they are named “rakes“ and I do them with the first of the methods that I am going to explain. Other combs mount thin needles, and are used after the rakes and with them are reached the different models of comb’s marbling. If they mount needles with a distance between them of more than one centimeter, I use the second method. But, if the distance between the needles can be equal or minor than one centimeter, then I recommend to use the third method that I will explain, that one of Woolnough, although this system can be used, if it is wished, for the manufacture of all the combs, any was the distance between its needles.

***

The first method:

5 cm. rake, large.

5 cm. rake, short.

Suitable to make rakes. It is the simplest. Only it is necessary to have a wooden strip of wood and a drill with a bit of the exact measurement, the same caliber, that the needles that we are going to use. On the strip of wood it is necessary to mark the distance between the holes to insert the needles, for example, every five centimeters. We can place a graph paper on the wood and indicate every interval. Or we can do it straight with a compass that moves this measurement. Then, simply, it is necessary to pierce every hole. If we use a support for the drill the holes will remain completely perpendicular to the wooden strip of wood without any effort; if we do not have it, it will be necessary to struggle a little to achieve it, although in a rake it does not have too much importance that all the needles stay absolutely perpendicular to the strip of wood and parallel between themselves. As soon as all the holes were done only remains to insert the needles, then, the rake is ready.

Advices: 1) make a set of two rakes, one measuring as the short side of the tray and other as the long side; 2) cut every wooden strip of wood longer ten or fifteen centimeters than the measurement of the sides of the tray, to be able to support it on the rims of it; 3) divide the measurement of the tray by the distance between the needles, despise the decimals and insert a needle less than the result, so that the rake has enough roominess to do the movements of go and return; 4) before placing the needles line the wooden strip of wood with tape of packing or something similar to waterproof it.

***

The second method:

The "gadget".

It is useful to make combs of more than one centimeter of distance between its needles. It is a method very similar to the previous one, a wooden strip of wood is used in the same way, but the very thin needles would slip in any hole done with a drill so it is necessary to fix them straight in the strip of wood. There is no problem with the measurements, a graph paper piece is placed on the wood strip and the emplacements of the needles are marked. But it is necessary to maintain the parallelism between them and also the perpendicularity with the strip of wood. Therefore they cannot be inserted to pulse because it would be a miracle that all of them were suiting. It is necessary to construct a simple gadget to fix them perfectly. There are necessary two pieces of pasteboard, not very thick, measuring approximately five centimeters wide, for a height equivalent to that of the needle that we are going to use less two centimeters. And a cardboard, of the same thickness of the needles, and of the same breadth and length that the previous pasteboards. This cardboard is cut by half his width. And then a pasteboard piece is placed on the table, above the two pieces obtained after the cut of the cardboard, with a needle between them, and completing this part of the gadget, another pasteboard on top. All the pieces must be stuck down, respecting the roominess of the needle, and cut the side excess of the cardboard, produced precisely by this. Finally this set should be mounted on a wood, a box or another similar support. It is placed on the strip of wood and the needles are sticking introducing them for the hollow between the pasteboards and beating with a small hammer. Due to this gadget all the needles will be introduced two centimeters in the strip of wood, and will remain perfectly parallel between them and perpendicular to the strip of wood by means of the box, which will act as a guide.

Advice: place a pair of strips of wood in the sides of which will be your comb, this will stabilize the whole.

***

The third method:

It is that one of Woolnough and Joan Ajala, the most precise, it serves to make any type of comb, but I recommend it especially to make the one centimeter combs or less of separation between its needles. It is the most complicated method, to be realized in three phases: the making of a stencil, the manufacture of the sections that will compose the comb and the final construction of this one joining them.

1st phase: the making of a stencil.

The first thing that we must construct is a stencil that will grant that all the sections we made will be equal.

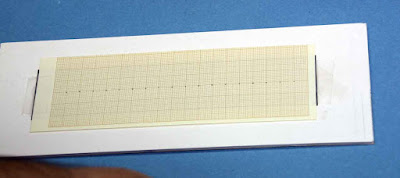

We need: a piece of pasteboard that will serve as base not to scratch the desk, the white piece of the photo, simply, a protection; a graph paper piece; the piece of plastic that will be the stencil, the black piece of the photo; a pencil and a needle of the same caliber as those that we are going to use in the construction of the comb, mounted, if it is possible, in a handle; if not it will be necessary to use a thimble.

We will place the plastic that will be the stencil above the protective pasteboard.

Above the stencil, the graph paper.

We will mark with a pencil the emplacement of every needle. It will be necessary to do a different stencil for every comb that we want to make. In this case, as it is shown, we are making the comb of one centimeter distance between its needles.

Finally with the needle mounted on its handle we perforate all the holes, carefully to not penetrate the protective pasteboard.

The completed stencil and, below, the scheme of Manuel Valero explaining this part of the process.

Advice: it is very usuful to establish the size Din-A4 as the width of every section of our combs. It is very manageable and, also, all the pieces that we need are easily founded in any stationery, if we adapt ourselves to this measurement. The plastic that it’s sold to bind thesis turns out to be perfect for the stencil and of every sheet we can extract a heap of stencils. The graph paper is also very easy to manage in this size. And, since we will see next, the cardboards and sheets of paper that we will need to make the sections are cut in three or in two pieces respectively.

2nd phase: the making of the sections.

Every section of the future comb consists of a waterproofed exterior cardboard and the piece in the M shape, that one in the illustration of Woolnough, which is placed inside it and which is the one that gives parallelism and perpendicularity to all the needles of the comb.

We will need: the same piece of protective pasteboard that we use earlier; the stencil that we did; a rule; a piece of pasteboard five centimeters wide that will serve to mark the half of the exterior cardboard; a cardboard piece, the piece in dark blue color of the photo, 10 centimeters long, of every Din-A4 sheet we will obtain three; adhesive tape to waterproof it; half of a current sheet of writing paper, size Din-A4; two penknives, one to mark and the other one to push and fit folds; the needle mounted in its handle already described and … many more needles.

The exterior cardboard:

The exterior cardboard should be waterproofed with a piece of adhesive tape covering its central part.

With the help of the pasteboard piece of five centimeters a line is marked on the center of the cardboard with a penknife …

… first folding the cardboard with the hands and later the edge is reinforced with another penknife.

The completed exterior cardboard.

The piece in M shape:

Starting folding the half of a sheet Din-A4 by the…. middle.

Later it is necessary to mark the line of the second crease, of half a centimeter to the first one. I help myself with a blue strip that has this measurement and with a penknife.

Now it is necessary to raise the rim of the crease.

And to double ahead, towards the number 1, the part marked with 2, which was beaten earlier to the table, under number 1. It is necessary to fold it just by the edge of the first crease, marked in the photo with two black lines.

Perhaps it was better viewed in the above part of this photo. Below one sees as the new crease is consolidated.

We already have the piece in M shape.

The laying of the needles:

Now it is necessary to place the pieces in order. On the protective pasteboard we mark a reference line and place above it the exterior cardboard, with the waterproofed part towards the table.

We fix it with a few pins.

The second is the M shape piece. Be sure to don’t put the rim of the piece on the line; it is the half of the crease in M which must coincide there, because the needles will have to penetrate the four parts of the crease.

Also we fix it with other pins.

Finally we place the stencil, aligning its holes with the line of reference marked in the pasteboard.

With a rule and a weight on the stencil this one remains fastened and quite ready to begin to perforate the holes.

What we must do carefully so that nothing moves.

This is the scheme of Manuel Valero of this part of the process. In the extended part one sees perfectly where it must go the needle, across the stencil and perforating the piece in M shape and the exterior cardboard, coming even into the protective pasteboard but without crossing it.

The stencil moves back. We can begin placing the needles.

On taking out the set, all the needles fit more or less until half of its length by each side.

The exterior cardboard is placed on the table and the needles must rest on the same plane.

It is a little hard work to straighten them up.

It is necessary to open the piece in M shape with a lot of care, little by little.

As soon as the piece was opened we see as every needle crosses four times the crease: there is no better method!

The final adjustment of every section:

It is necessary to close the exterior cardboard.

And to open it again to verify if the piece in M shape remains completely exact in its interior. It is very frequent that it will be necessary to make a small correction.

With the help of a stop all the needles will line up.

No more to do now than to stick down the interior sheets and the cardboard.

First the outside parts and then the central one. But, attention, give a press blow after sticking down every part, photography is too quick.

The paper surplus cut out.

And we already have a section of the completely finished comb.

The manufacture of the comb:

The comb is made sticking down several sections of these “needles sandwiches”, as they are named by Manuel Valero, so many sections as they are necessary to reach the length of the comb that we want to do, to two pieces of pasteboard that will be the support of the comb, one goes below and the other one over the sections, and, naturally, it is necessary to stick down it on parts and to fit all the pieces.

The latter diagram of Manuel Valero shows how two sections are joined. It should coincide the last needle of the first section with the first needle of the second section, in order to verify the distance and to fit the alignment. Cut a small piece of both sections with a cutter, there where they remain joined, therefore the union will remain perfect. Of the two numbered needles 1 and 2 on the diagram, one of them gets lost in this assembly.

After gluing the sections to the low pasteboard, and to the top one, a wooden strip of wood is added to the comb.

The comb is already finished.

I have taken hundred times more in explaining it that which is taken in doing it.

I assure it to you.

*

The best combs that I have ever made were doing following this method. I do not know another better way of doing them, especially the thinner combs; it is an essential method if the two millimeters comb is needed. The pasteboards can be also waterproofed, as well as the wooden strip of wood, which you already know that it is longer than the comb to rest on the side rims of the tray, so it is possible to control its movement evenly. The three brown pieces on the latter photo are three screws that can be placed further down or above as the level of the bath is diminishing or as we refill the liquid of the tray; this way nor the needles will remain over the surface of the liquid not touching it without designing, a thing sometimes happens, nor the pasteboard will touch the liquid and ruin the pattern.

***

2 comments:

Onde podemos encontrar este livro antigo para comprar, estou localizada em São Paulo, no Brasil.

Obrigada

Célia

Celia:

The Woolnough's book is very appreciated and reach great prices. I've founded my copy in Abebooks.com, maybe Amazon could works also.

They are 3 editions, the first one is:

Woolnough, C.W.

The Art of Marbling as Applied to Book Edges and Paper... with a brief notice of its recent application to textile fabrics. London: Alexander Heylin, 1853. 80 pages.

It seems that some of these items were binded in marbled fabric maybe made by the author himself, I've never seen a copy.

The second edition was published the next year, in 1854, and is similar to the first.

And the third edition is:

Woolnough, Charles.

The Whole Art of Marbling. 3rd. ed. London: George Bell & Sons, 1881. 82 pages.

This last has edition has new models and some samples of mecanic marbling made by W. Mansell, as a complement to the main body of samples made by the author or by his workers following his instructions.

I hope this helps.

Post a Comment